On-Demand Manufacturing for the Energy Sector

Learn why more energy companies are turning to on-demand manufacturing.

Download Use CaseScale On-Demand Manufacturing in the Energy Sector

Energy companies have vast networks of aging machines, often in remote locations, making it difficult to get parts as needed without significant revenue loss due to operational downtime.

On-demand manufacturing methods can reduce lead time and improve access to parts by producing them closer to their end-use.

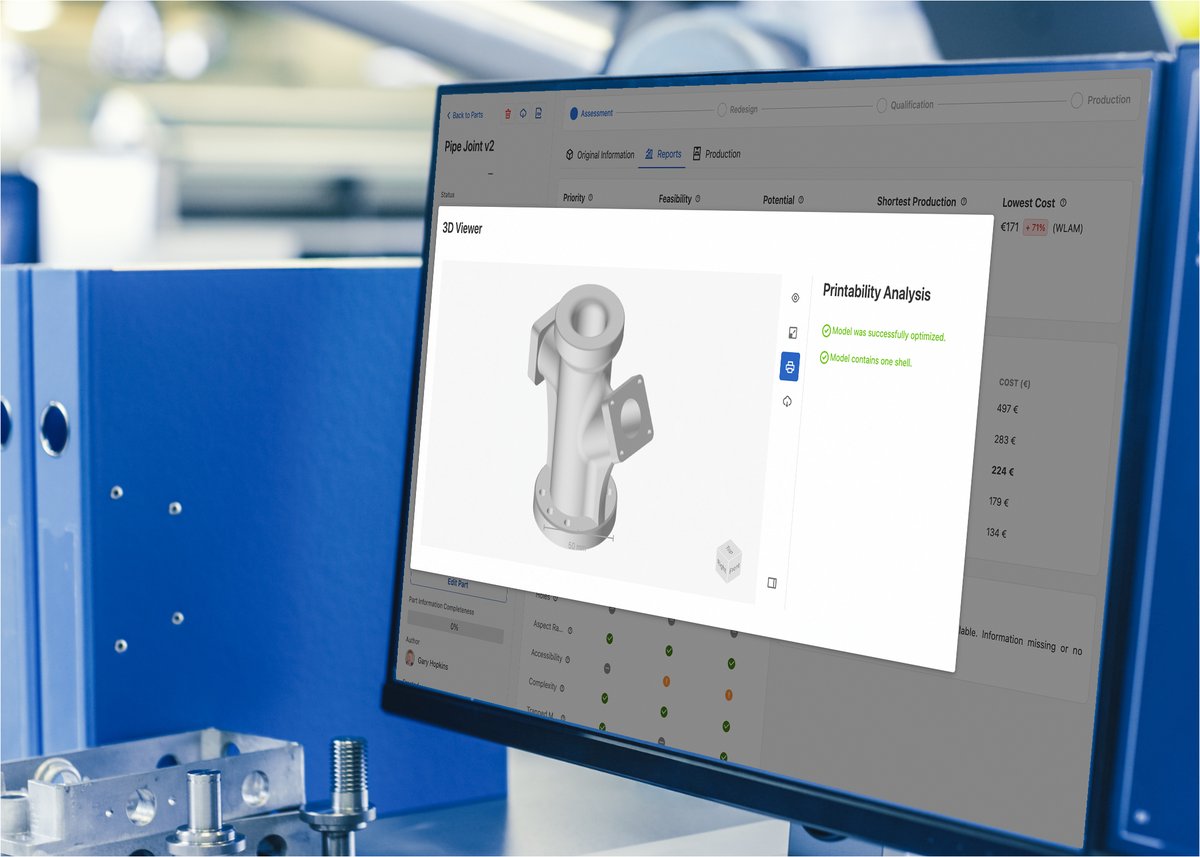

Adopting on-demand manufacturing methods in tandem with software to identify qualified part business cases and manage a network of approved suppliers provides energy sectors with the resources to keep equipment operational and reduce the financial impact of machine downtime.

O&G Companies Use Additive to Shorten Production Lead Times

Learn how a multinational oilfield equipment provider transformed a costly two-year lead time into just weeks with additive manufacturing. Faced with unavailable suppliers and long wait times for new molds, the company empowered its engineers to explore innovative production methods and alternative suppliers.

Download our case study to learn how they overcame supplier shortages by using software to determine the best additive manufacturing technology.

Download Case Study

3YOURMIND is an Experienced Energy Partner