EOS and 3YOURMIND Automate 3D Part Identification

3YOURMIND's part screening and business case functionality scans existing part inventories to determine optimal parts for Additive Manufacturing and guarantee a profitable transition into Industry 4.0.

PRESS RELEASE

25th April 2017

3YOURMIND/Berlin

These recommendations allow businesses to immediately begin 3D printing profitably. By ensuring the selection of the optimal components for production from existing inventories, 3YOURMIND removes the primary hurdle for companies as they shift resources to Industry 4.0 and the digitization of production.

Automated Analysis of 3D Printing Suitability

3YOURMIND was founded with the mission of simplifying the processes and ensuring the profitability of industrial 3D printing. Their Enterprise Platform and eCommerce Solution guarantee that uploaded components are printable and optimized for the selected material as well as ensuring that 3D resources have maximum utilization. However, while working with some of the largest companies in Germany they noticed a distinct problem inhibiting a wider adoption of Additive Manufacturing throughout the production chain:

Leading producers are managing part inventories with components numbering in the 100,000s with 2-4,000 new parts coming online each month. Determining which of these components are suitable for industrial 3D printing is done via manual part analysis or expensive 3rd party reviews of inventories.

To address this fundamental need facing every enterprise business as they transition larger portions of their production to Additive Manufacturing, 3YOURMIND worked together with EOS to digitize the analysis process and deliver an automated analysis of component suitability for industrial 3D printing.

“For several years we have helped our customers to identify the most suitable parts for industrial 3D printing. We are very pleased to see that thanks to our cooperation with 3YOURMIND an automated software solution now enables a faster part identification than ever before.” Fabian Krauß, Business Development Manager at EOS.

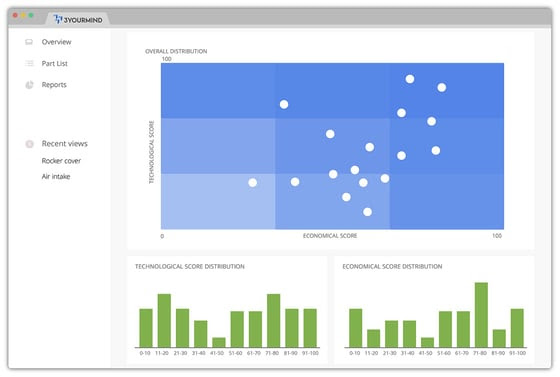

After entering basic information about the parts that need to be produced, enterprise businesses can perform an automated scan of their entire inventory database. The analytic reports leverage over 10 years of experience from Additive Manufacturing experts to determine exactly which parts are best suited for industrial 3D printing. Companies immediately save time and money when they implement 3D Inventory Analysis by identifying the parts that are technologically viable and economically profitable.

How to Enter Industry 4.0

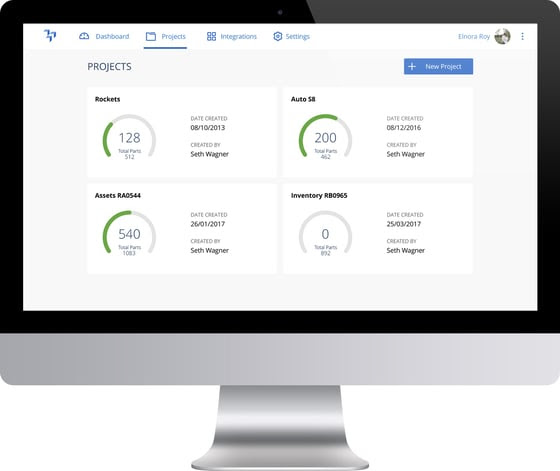

Part screening and business cases a solution for businesses of all sizes to efficiently enter Industry 4.0 and optimize their use of industrial 3D printing. Its aim is to scan an entire part inventory and provide a detailed report of parts that represent the highest potential gain by transitioning to industrial 3D printing. The platform essentially provides a blueprint for shifting the proper resources and guaranteeing a successful outcome. Additional tools to input information about in-house 3D production resources and external industrial 3D printing suppliers will further customize the component recommendations to your specific capacity.

For top 100 companies who are also searching for clear pathways to optimize their use of Additive Manufacturing and who are managing huge volumes of new and legacy parts, the AM Part Identifier can also be linked directly to their part database to receive updated reports in real-time as additional parts are added or as advances in 3D print technologies enable cost-effective production of components and materials. It enables enterprise and medium-sized companies to make smart decisions about where to begin implementing industrial 3D printing.

“The mission of 3YOURMIND is to facilitate the simple implementation of professional Additive Manufacturing for companies of all sizes. Part screening and business cases ensures that optimal production can begin right away with cost and time savings to ensure that the possibilities of AM become a core part of their business model." Stephan Kühr, CEO, 3YOURMIND.

Cost-Effective From Day 1

There is clear evidence from many industries that the implementation of industrial 3D Printing will result in huge cost savings. But one of the primary inhibitors to shifting more components to these new production methodologies is that all the existing processes are centered around standard manufacturing techniques from the training of engineers to the PLM software workflows to detailed post-processing standards. The selection of parts for Additive Manufacturing is currently being carried out by a small group of experts with a high percentage of manual processes as part of the operation.

Part screening and business cases removes all of those questions so that companies can immediately focus on the parts which are suitable for industrial 3D Printing and begin implementing smarter and more efficient production.

3YOURMIND continues to expand to ensure that companies have a clear pathway to the benefits of 3D printing, from design to production.

About EOS

EOS is the world’s leading technology supplier in the field of industrial 3D printing of metals and polymers. Formed in 1989, the independent company is a pioneer and innovator for comprehensive solutions in additive manufacturing. Its product portfolio of EOS systems, materials, and process parameters gives customers crucial competitive advantages in terms of product quality and the long-term economic sustainability of their manufacturing processes. www.eos.info

Press Contact:

EOS GmbH Electro Optical Systems

Claudia Jordan

Press Officer

Phone: +49 89 893 36 2134

e-Mail: Claudia.jordan@eos.info

About 3YOURMIND

3YOURMIND develops industrial 3D printing software platforms for Industry 4.0 workflows. Our enterprise solution is already being used by DAX 30 companies and forward-thinking businesses around the world. From our offices in Germany, Poland and the USA, we are optimizing production processes for industrial 3D printing to drive the adoption of this technology for businesses worldwide. The 3D design-to-production platform has already been recognized with prestigious awards including the 2016 German Innovation Award.

To learn more about the part screening and business cases visit our solution page.