How to Analyze Technical Drawings for Additive Manufacturing

Are you struggling to find additive manufacturing use cases from your existing parts? Here's how 3YOURMIND's 2D Drawing Analysis instantly helps you find AM use cases.

One of the major implications of additive manufacturing is its potential to produce spare parts on demand and close to the point of need. However, before companies can begin clicking 'print,' there are several significant challenges to overcome.

There are two issues we've seen businesses struggle with the most. One is knowing which of their traditionally manufactured or obsolete parts are technically feasible to produce with additive manufacturing. The second is knowing which parts have the potential to lower costs.

At 3YOURMIND, we recognize that many companies don't always have 3D part files or standardized data. Technical drawings can be over 50 years old and may be incomplete or hard to read.

Last year, we introduced a new feature to help engineers examine data from technical drawings to quickly determine whether a part offers a solid economic use case for additive manufacturing. We did this to better equip AM engineers to decide which parts should be optimized for AM.

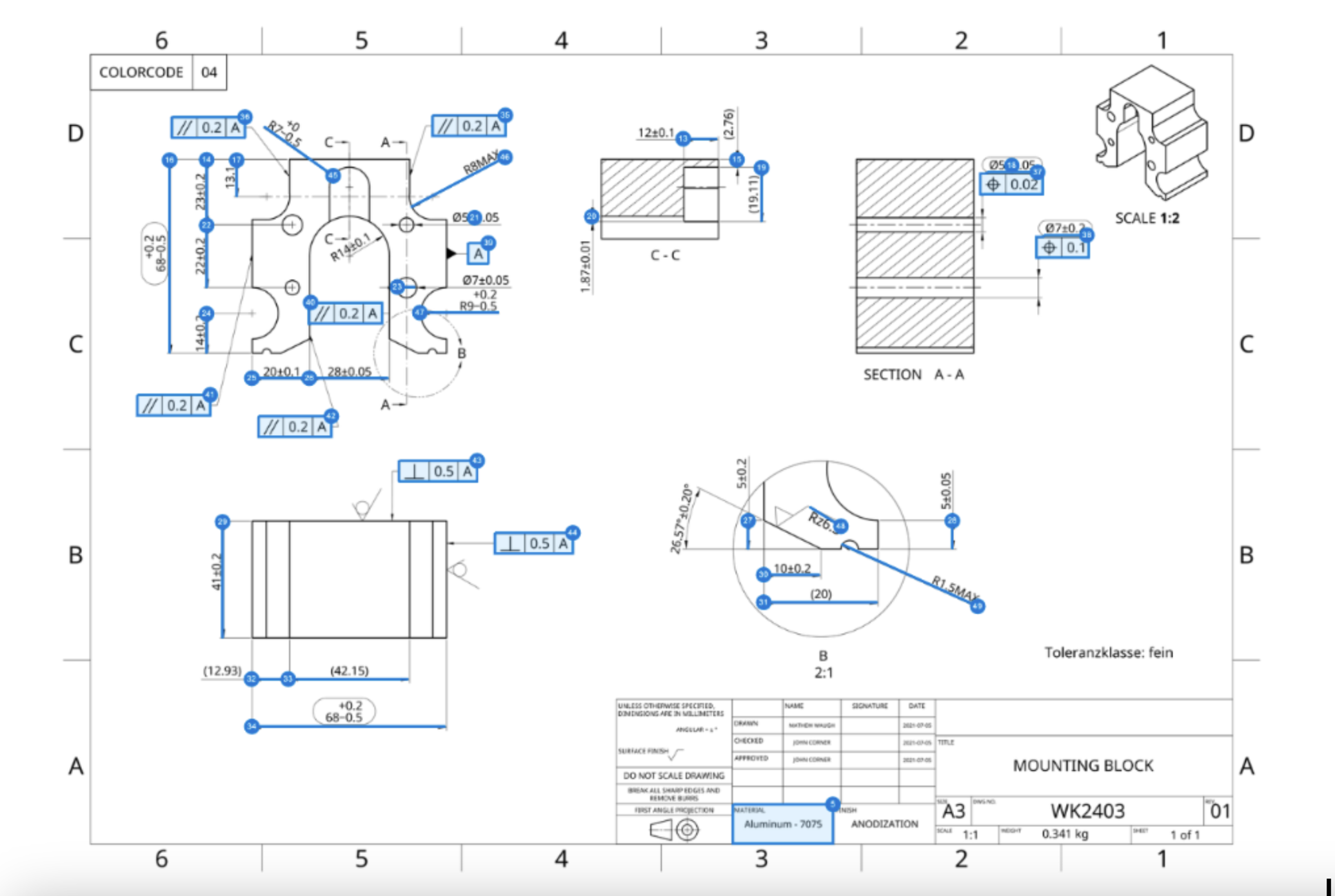

Example of a technical drawing.

Our 2D technical drawing analysis, powered by Werk24, uses AI and machine learning to 'read' technical drawings and extract data, which is added to the customer's part list on 3YOURMIND. This data includes essential elements like part names, dimensions, materials, material class, and any weight or volume information that might be included in the technical drawing.

Although this functionality is quite simple and may not receive the greatest fanfare, the magic happens when our users include economic information. For example, the current cost of the part using traditional manufacturing methods, average lead time in days, annual demand quantity, and the number of downtime hours that can occur to replace a part that is not in stock.

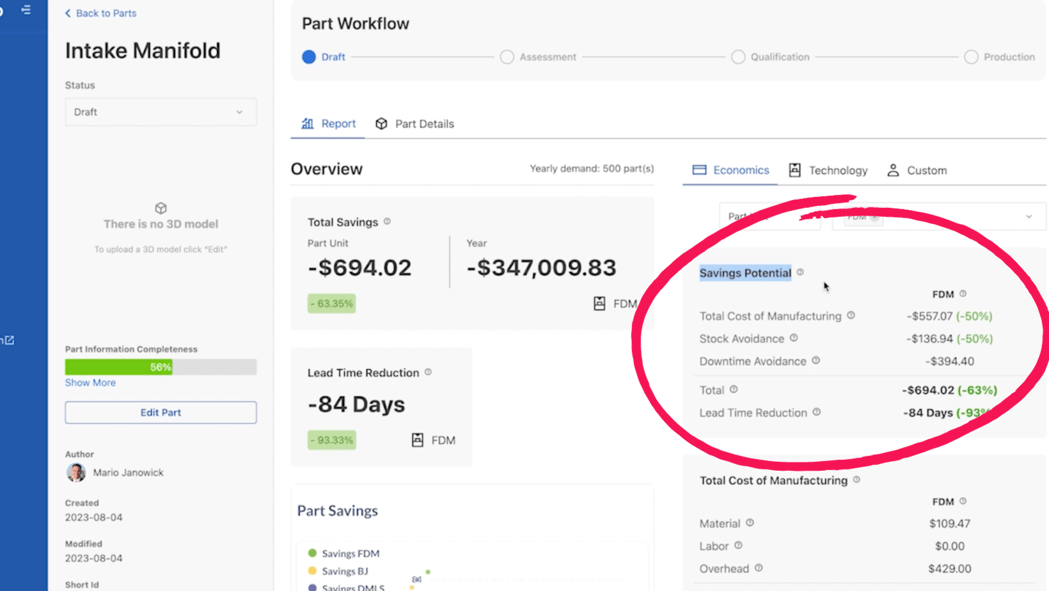

With these details, 3YOURMIND calculates savings potential based on the total cost of manufacturing (i.e., material, labor, and overhead costs) and savings that can be achieved by decreasing warehousing stock, mitigating downtime, and reducing production lead time.

Here's how it works:

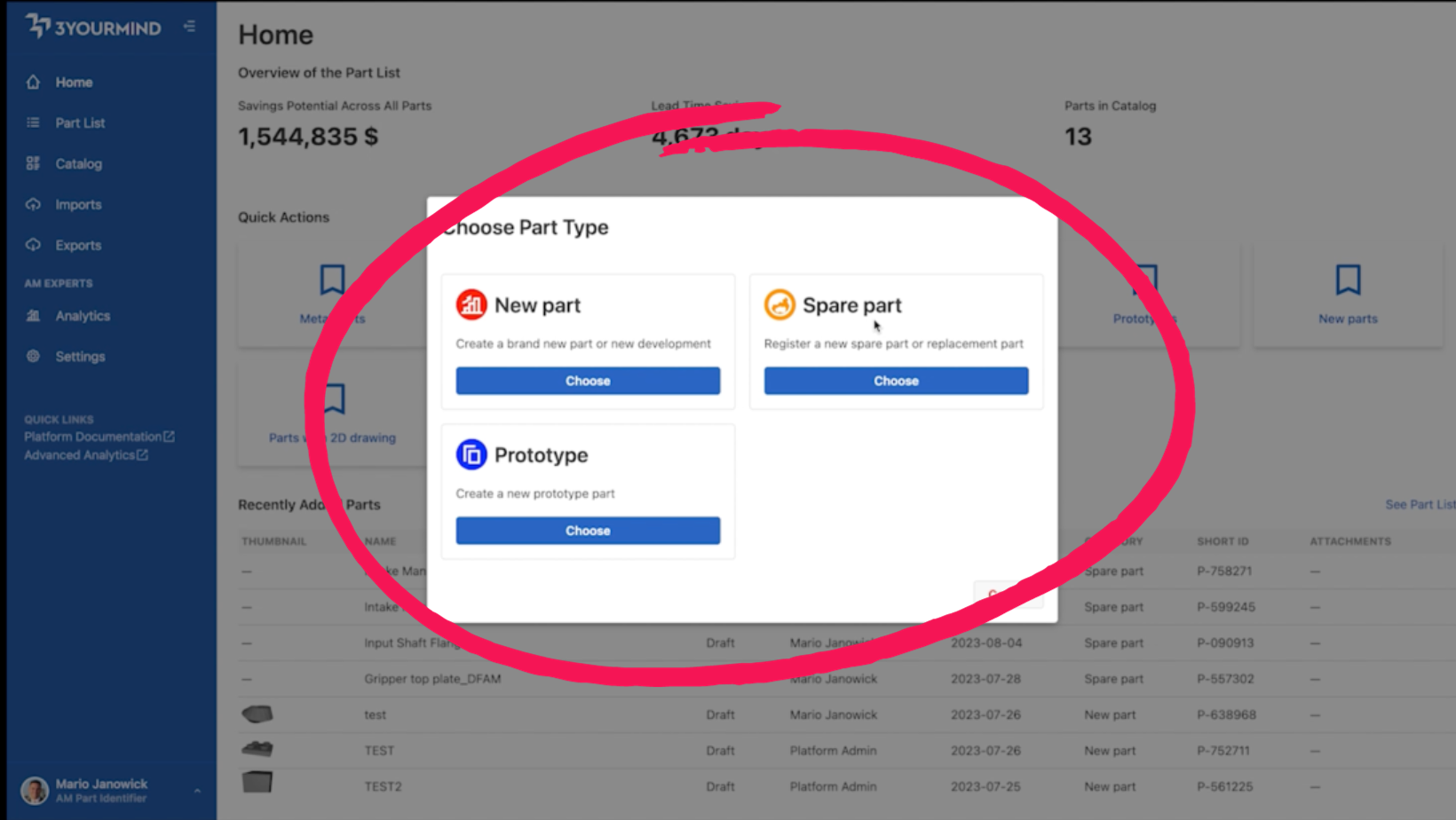

1. Create a New Part in 3YOURMIND

In 3YOURMIND, users can navigate to the Part List Overview page located on the Homepage. From here, select 'add new part,' select which type of part you would like to create.

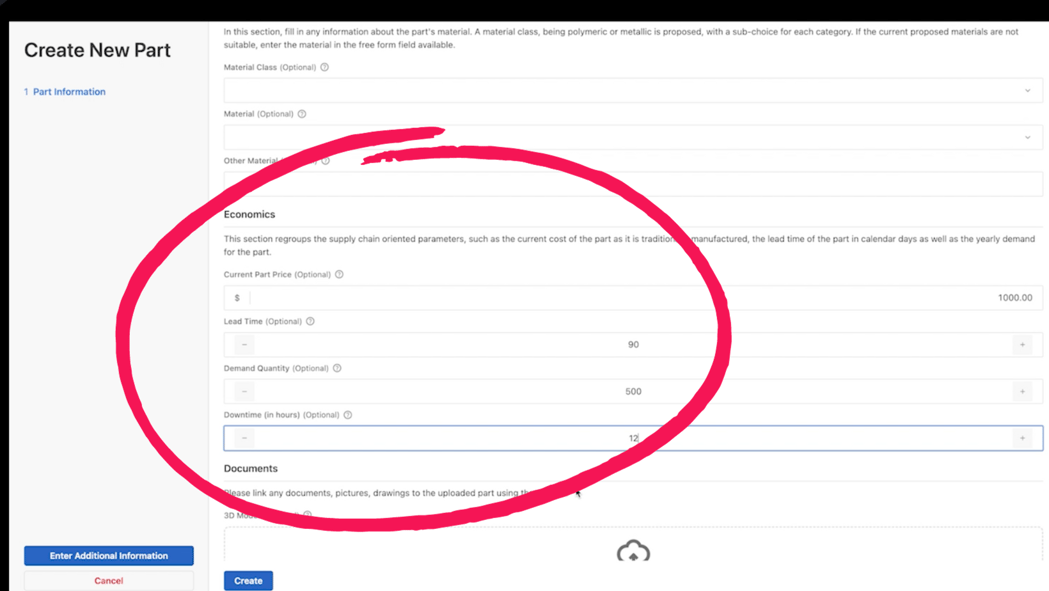

2. Add Economic Details to Access Savings Calculations

From the Create New Part page, you have the option to include economic information about the original part, including the current part price, lead time, annual demand quantity, and annual number of downtime hours that occur due to part replacement.

It's important to note: If you choose not to include this information, 3YOURMIND will be unable to calculate the total cost to manufacture this part using additive.

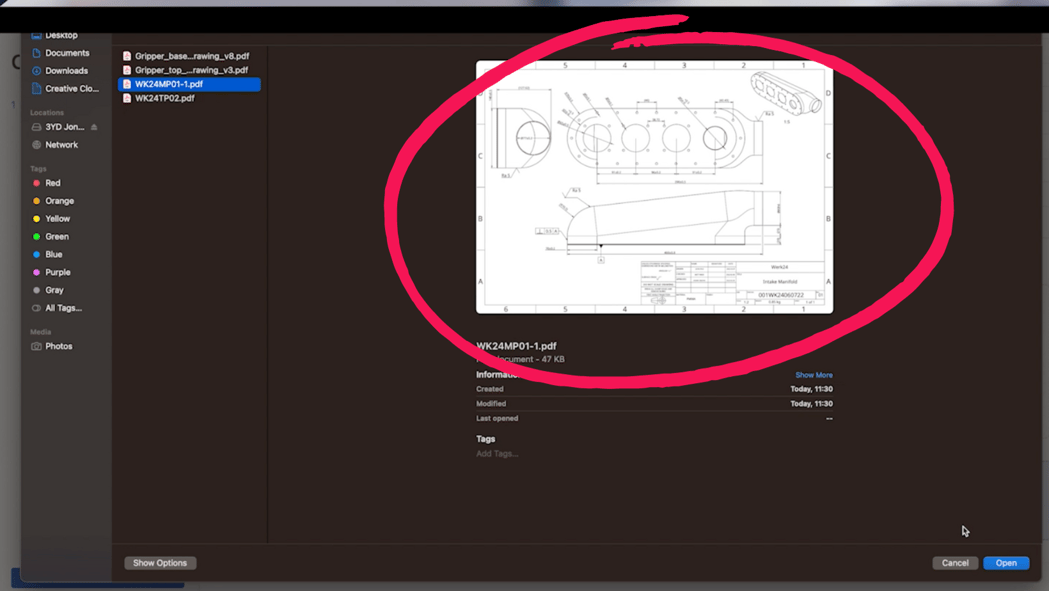

3. Upload Your Technical Drawing to the 3YOURMIND Platform

Once you've added the part information you'd like to include, you can begin uploading your technical drawings for 2D analysis.

3YOURMIND supports the following upload requirements:

- File type BMP, JP2, JPEG, PNG, TIFF, TIF, PDF

- Minimal resolution of 200dpi

- Maximum file size of 10MB

4. Review Cost Savings Potential

If you included economic information, you can view the savings potential from the part overview after the drawing has been analyzed.

3YOURMIND creates these calculations based on the economic information included, the material, and the dimensions of the part.

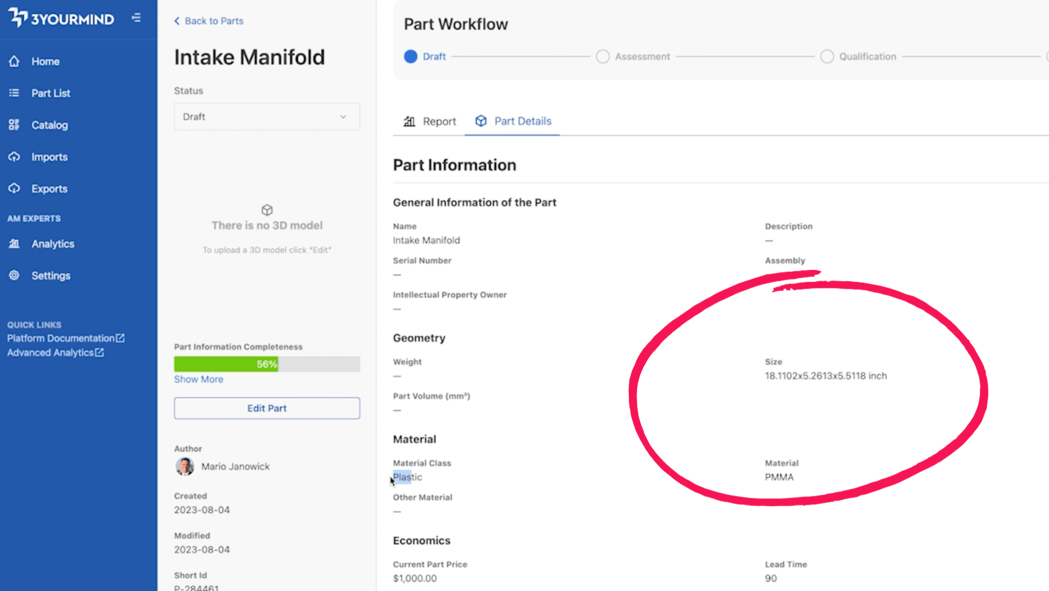

5. Review Part Dimensions and Materials Populated to the Platform

From the Part Details tab, you can view the information that was extracted from the technical drawing. If you need to make changes or add additional information, you can do so by clicking 'Edit Part.'

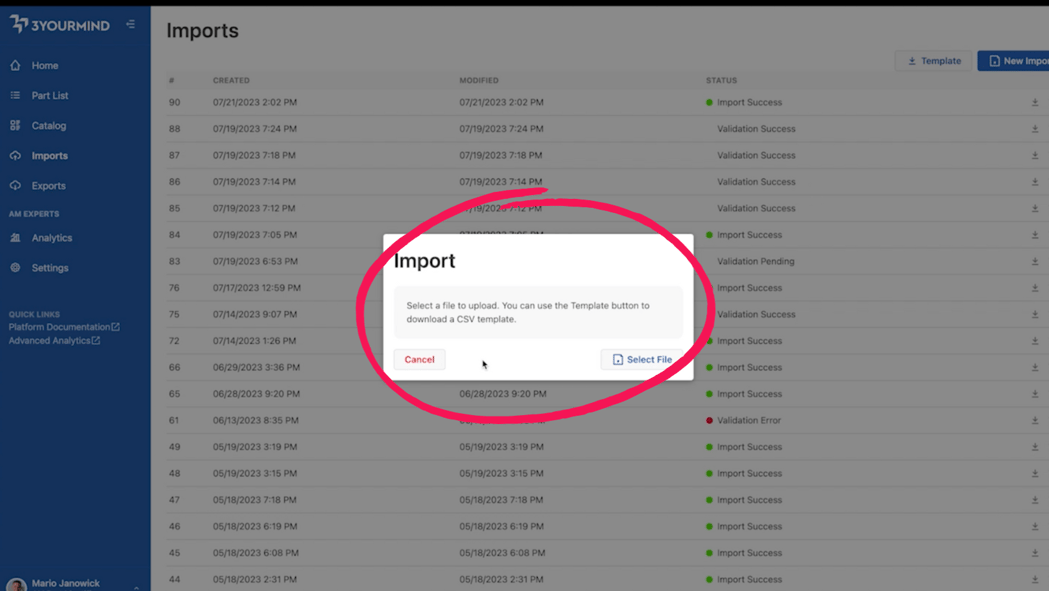

6. Need to Analyze More Parts? Try Bulk Importing

With the bulk import method, users can gain a quick overview of which parts "pass" or "fail" from a cost-savings perspective. This saves engineers time by creating a priority list of parts that can and should be optimized for additive manufacturing.

To learn more about bulk importing, send us a message.

Want to See the Full Demo? Watch the Video

3YOURMIND empowers companies to realize their full additive manufacturing potential by finding additive manufacturing use cases in their existing parts inventories. Contact us today to get started.