How to Distribute Production With Additive Manufacturing

Are you ready for distributed production? Read this article to find out whether your organization meets the requirements.

In the ever-evolving landscape of modern manufacturing, the concept of distributed production has gained prominence, especially with the advent of additive manufacturing, also known as 3D printing.

Distributed production involves decentralizing manufacturing processes, allowing companies to create components or final products in multiple locations. While this approach offers numerous benefits, it also poses significant challenges, particularly in terms of managing and sharing the data required for seamless operations. This article delves into the intricacies of distributed production in the context of additive manufacturing and explores challenges and solutions for overcoming data obstacles.

Is Distributed Production the Future?

If additive manufacturing enables the creation of three-dimensional objects layer by layer, providing unparalleled flexibility and efficiency, then distributed production takes this one step further. Distributed production effectively decentralizes manufacturing processes across various locations using additive manufacturing. For companies in critical industries like energy, defense, and transportation, where maintaining operations is paramount, the ability to optimize resources, shorten logistics chains, and respond more quickly to part demands is a compelling business case.

Here are three reasons distributed production is attractive for organizations that rely on part availability to sustain equipment and operations:

Localized Manufacturing:

Localizing manufacturing helps create customized or on-demand products without the need for extensive shipping and warehousing.

Supply Chain Resilience:

By distributing production capabilities, companies can mitigate risks associated with centralized supply chains. This is particularly relevant during disruptions, such as natural disasters or global crises, such as the COVID-19 pandemic, where supply chain disruptions rocked business operations and consumer spending habits.

Reduced Lead Times:

Distributed production minimizes lead times as products can be manufactured closer to the end users. This agility is particularly advantageous for critical industries like defense and energy that require the availability of spare parts to sustain equipment. However, maintaining an inventory of spare parts in remote locations creates significant logistics and warehousing challenges. Distributed production enables operators in the field to print parts closer to their point of need and without holding large quantities of parts in stock.

Pictured: Software can connect production capabilities worldwide.

Pictured: Software can connect production capabilities worldwide.

Why Isn't Everyone Building Distributed Production Models?

Currently, several factors contribute to the limited adoption of distributed manufacturing models.

Firstly, the upfront investment in advanced technologies (like additive manufacturing) and the necessary infrastructure required to support those technologies can be substantial, deterring some companies from making the initial leap. Additionally, even with a clear additive manufacturing investment strategy, it can be challenging to determine which use cases are the most cost-effective and scalable for serial production to generate a return on investment.

Secondly, data poses a significant hurdle. Distributed legacy data, unstandardized industry practices, and interoperability challenges further complicate seamless collaboration between production facilities, equipment, and even software.

However, these are problems that can be solved. At this juncture, it's not a matter of if a distributed production is possible – now it's important to consider how to build a distributed production model. In this sense, there are two critical areas that, without prior planning, can cause disruption down the line:

• First, what parts should be printed using additive manufacturing?

• And second, how can organizations securely manage data for distributed production?

Knowing what 3D parts should be printed is an important first step in distributed manufacturing.

Knowing what 3D parts should be printed is an important first step in distributed manufacturing.

Solution: Figure Out What Parts Should Be Manufactured With Additive

Additive manufacturing can reimagine common objects or parts in a new way. And though additive manufacturing earns points for novelty by being able to 3D print sports equipment or side tables for home decor, they're hardly the type of use cases that most organizations need.

Instead, businesses want the parts they already use but produced faster, closer to where they're used, and, ideally, cheaper. But, finding that sweet spot of part availability and cost is a challenge. Businesses don't want to 3D print a part that can be produced with injection molding for a fraction of the cost. But, there are certain parts you cannot afford to not have replacements for because they can stall your operations.

In the context of organizations whose operations rely on sustaining legacy or obsolete equipment, finding manufacturers to produce spare parts can be challenging, often taking months or longer to remanufacture. Because production lead times can be so long, businesses take on physical costs and tie up capital to store overstock parts 'just in case' they're needed months – or even years – in the future.

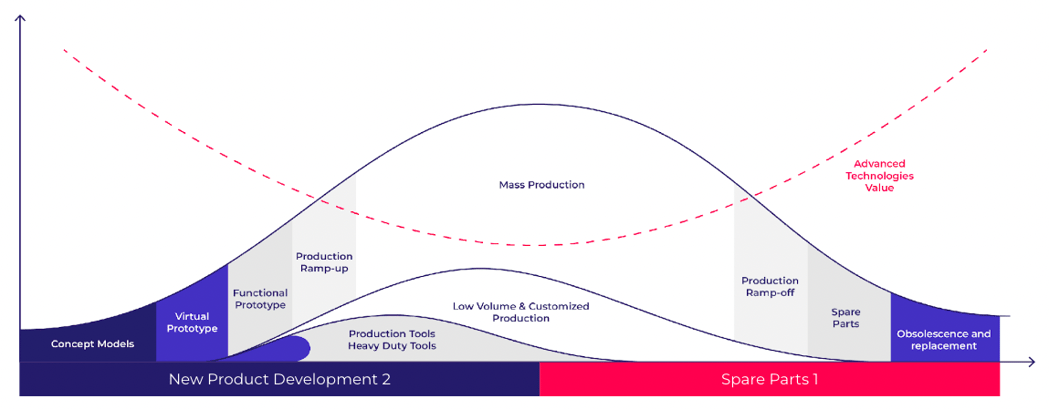

Graph demonstrating a common product lifecycles for manufacturing.

Fortunately, there are additive manufacturing software solutions available on the market that help simplify the process of identifying parts for additive manufacturing. Part identification software can evaluate 3D part files, 2D technical drawings, or even simple data points to determine whether a part can be produced with additive manufacturing. Software can also examine these parts to determine whether there are strong business use cases. For example, whether the cost of an additively manufactured part is justified based on the warehousing and lead time savings it generates.

Additive manufacturing applications engineers are the go-to experts to determine the best applications, and part identification can aid in the decision-making process. Rather than going through hundreds, even thousands, of part designs individually to determine if there's AM feasibility, application engineers can use software to eliminate unsuitable parts quickly. By doing this, engineers can focus on qualifying cost-effective applications that are already suitable for additive manufacturing or can allocate resources to turn parts with strong business cases from additive manufacturing no's into yes's

Solution: Get in Front of Your Data Problem to Distribute Production

Nowadays, everyone talks about the benefits of data to drive decision-making and empower business operations. But, for all its positives, there is a dark side to data. How do you know what data you need, how do you use it, and most importantly, how do you manage data and keep it secure?

Here are several ways to assess whether your data is ready for distributed production:

Your Data is Standardized

If you have thousands of parts in your inventory that are decades years old, there's a pretty good chance your data isn't standardized. Maybe you have different file formats or naming conventions that have changed over time. It's okay; you're certainly not alone.

However, there may be clues hidden in your data that can suggest which parts may be strong cases for additive manufacturing. But, if your data is not standardized, you may have trouble finding them.

Standardizing these data formats is essential for seamless communication between distributed production facilities. 3YOURMIND has experience working with the U.S. Marine Corps System Command’s Digital Manufacturing Data Vault to standardize distributed data from legacy and sustainment spare parts and determine which parts offer robust additive manufacturing use cases.

You Know Who Is Approved to Access Parts (And Who Isn't):

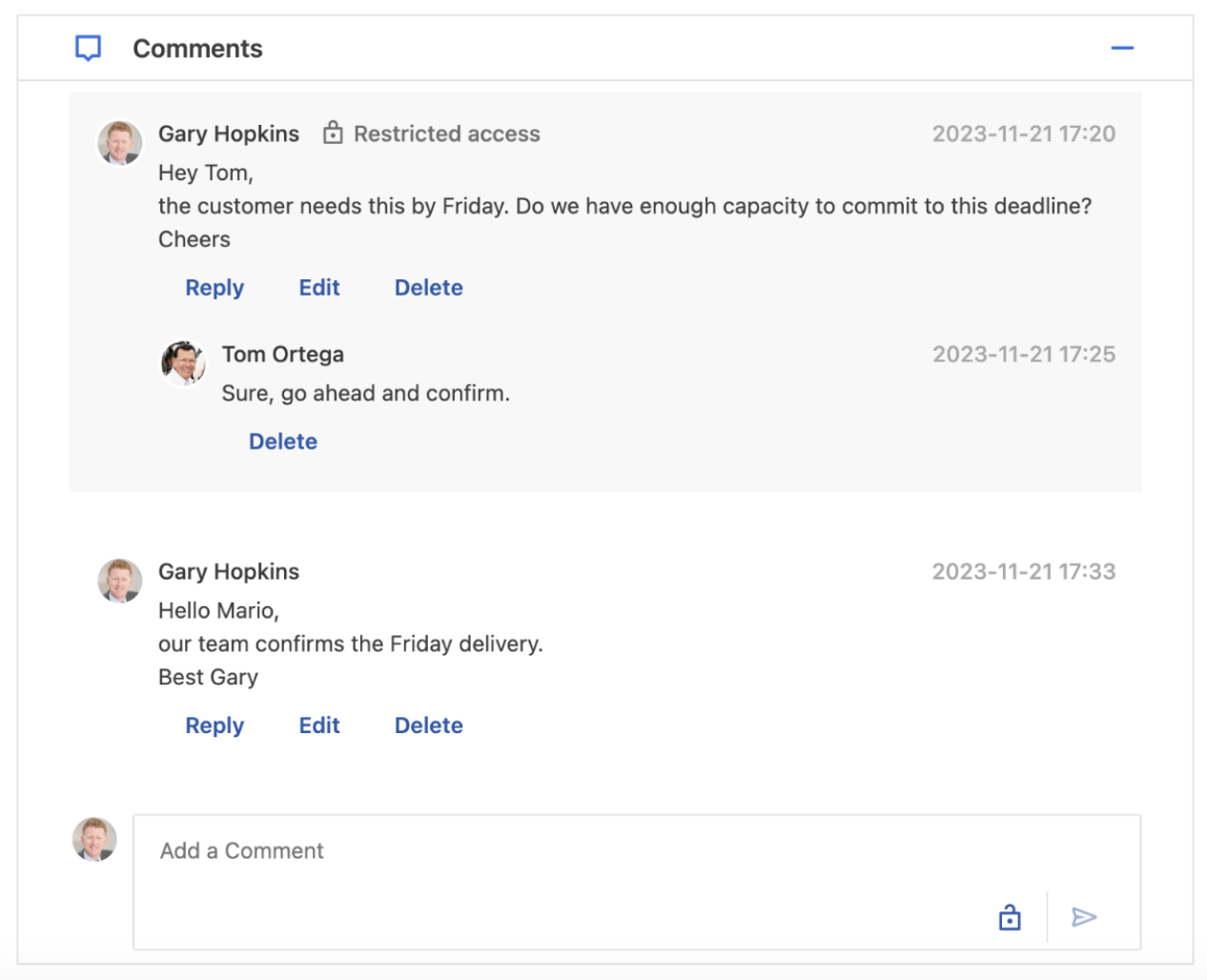

Collaboration is crucial in a distributed production model. Ensuring seamless data access and sharing between geographically dispersed facilities requires robust digital infrastructure. You need a centralized work environment (not just e-mails and cloud drives) where colleagues can leave comments, assign tasks, and manage part projects. 3YOURMIND enables colleagues to work together to optimize parts before and after prototyping, embedding improvements into each new iteration.

With 3YOURMIND, you can communicate directly on parts rather than e-mails – all while controlling who has access.

That said, it also requires some safeguards – especially when working with people outside of your organization. With 3YOURMIND, your organization has a workspace that enhances collaboration for your employees and improves information sharing while limiting access to approved users only.

You've Thought About Your Intellectual Property

Protecting intellectual property is a significant concern in distributed production. Distributed production, as the name suggests, distributes production and build information across different facilities, enabling machines in different locations to print 3D parts on-demand. As this production model scales to include external suppliers and facilities, securely sharing building information while simultaneously protecting intellectual property information becomes paramount.

Restrict access to 3YOURMIND's 3D viewer to prevent IP exposure

Not sure how to do that? The 3YOURMIND digital inventory module restricts access to those who can download build files and who can utilize the platform's 3D part viewer to prevent potential extraction of 3D files, ensuring maximum IP protection. This enhancement is specially tailored for organizations looking for a more controlled internal environment, offering them an added layer of IP protection.

You Know Whether Operations are Cloud or On-Premise:

Cloud-based and on-premise distributed production networks each have their pros and cons. Depending on the size, scope, and geographic location of your business, your distributed production operations may be cloud-based or hardwired on-premise. Cloud-based operations are scalable and faster to implement, but on-premise networks offer increased security and availability.

![]() 3YOURMIND is available on-premise or securely via the cloud.

3YOURMIND is available on-premise or securely via the cloud.

3YOURMIND has extensive experience integrating into complex, on-premise installations customized to the exact requirements of your organization. We take security seriously and have experience following the Department of Defense's security technical implementation guides (STIGs) for customers like the U.S. Navy and Phillips Corps. Federal Division.

We also understand the importance of scalability. We can deploy our software in our secure, shared SaaS infrastructure as a dedicated cloud instance that can grow with your operations. Our cloud-based capabilities are just one reason why customers like JSSB and Arkema choose 3YOURMIND.

Simplify Data Management for Distributed Production

3YOURMIND is a centralized platform that simplifies data management for distributed production. Companies can seamlessly connect and organize additive manufacturing data across multiple locations safely and securely.

With 3YOURMIND, organizations can locate strong additive manufacturing business cases with their existing data and build digital parts inventories, enabling them to send and print part orders to production facilities worldwide. As a result, companies can get the parts they need when they're needed and closest to their point of need.

Ready to get started? Tell us how your company plans to use distributed manufacturing.