How Top Space Companies are Profiting From 3D Printing

Aerospace companies are poised for significant gains by integrating additive manufacturing. They benefit from reducing weight at every opportunity so lightweight components make a huge difference in cost and feasibility for space. Remote, on-demand, and small batch production are also significant factors for space travel. And the real future is in producing new components directly in space from other parts.

Photo Source: Boeing

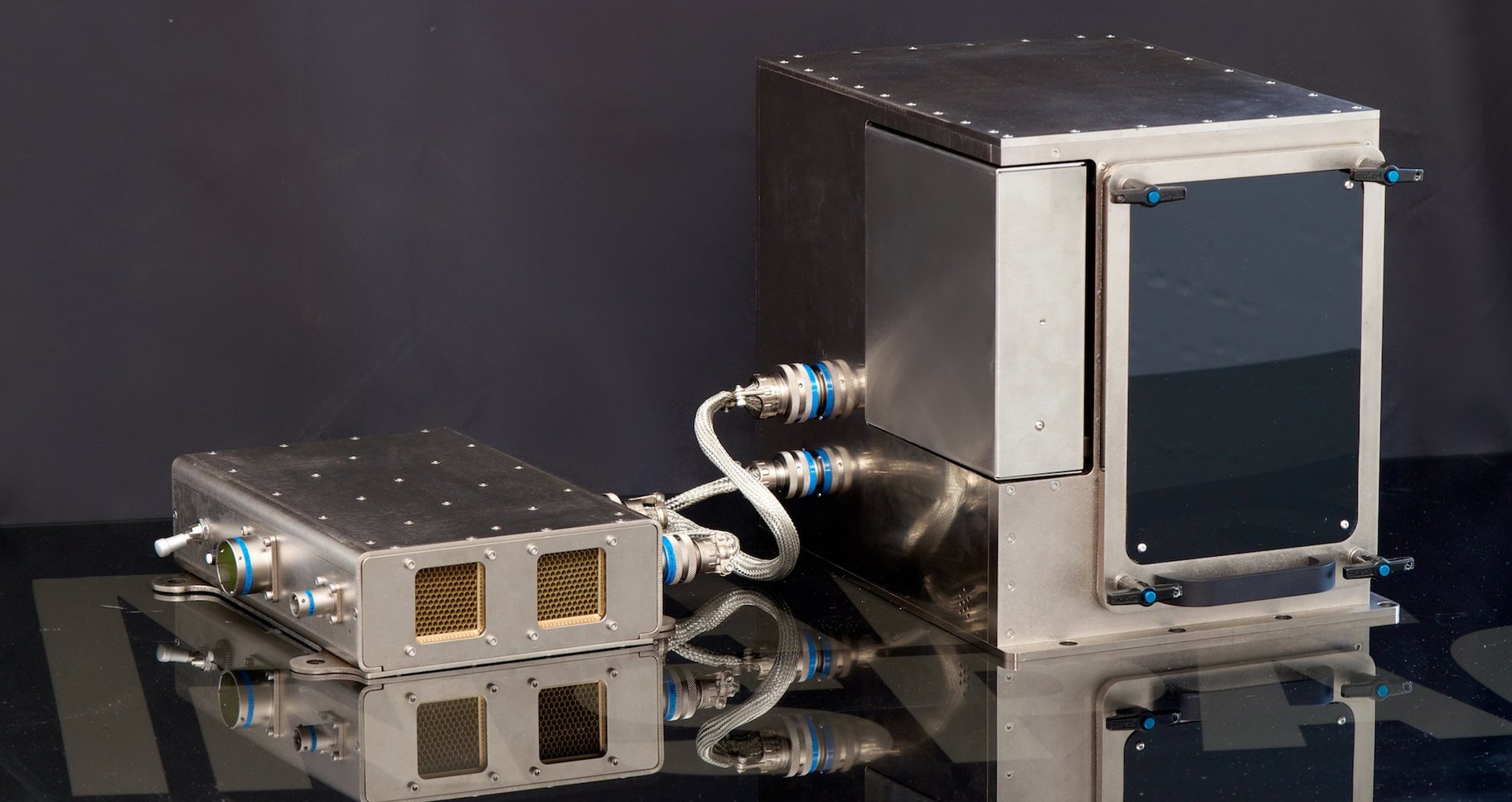

Photo Source: BoeingIf you can transmit a file to the station as quickly as you can send an email, it opens up endless possibilities for all the types of things that you can make from CubeSat components to experiment hardware. We even may be able to make objects that previously couldn't even be launched to space.

Niki Werkheiser, Space Station 3-D Printer Program Manager, at NASA's Marshall Space Flight Center in Huntsville, Alabama.

Photo Source: Made In Space

Photo Source: Made In SpaceThe Most to Gain

In 2013 NASA opted to invest heavily in 3D printing for two primary reasons: remote Production and On-Demand Production.

As 3D printers approach small factories in terms of quality, NASA has been able to produce small batch or single parts without the re-tooling required in traditional production methods. Digital technologies enable this “re-tooling” of the factory to be completed with the upload of a new design file. This represents a huge savings in terms of money and just as significantly time.

Additive manufacturing, or 3D printing, is a key technology for enhancing space vehicle designs and manufacturing and enabling more affordable exploration missions. The technology has the potential to influence spacecraft built for leaving Earth and spaceships and landers for visiting other destinations.

Niki Werkheiser, NASA's Marshall Space Flight Center in Huntsville, Alabama.

Just as we see the potential of 3D Printing to redefine logistics, similar benefits such as remote operation, reduced space requirements, multi-material manufacturing with a single machine, and the removal of extra steps for assembly are also helping to redefine “space logistics.”

Photo Source: NASA

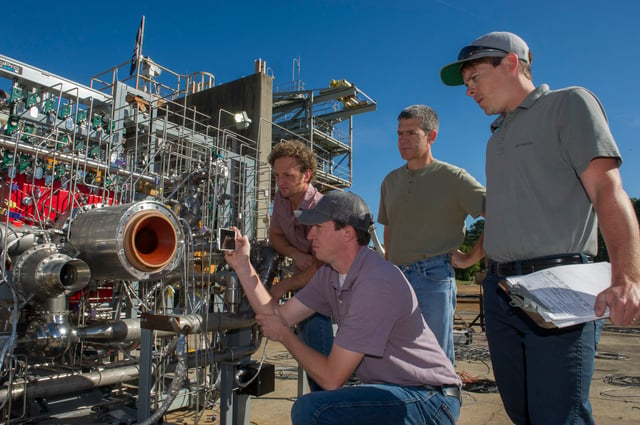

Photo Source: NASARocket Engines and High-Performance Parts

The improvement of processes in terms of efficiency, design, and performance is also among the benefits obtained in the technical manufacturing of high-performance parts like engine valves. By the end of 2015, NASA announced that their engineering team was testing a completely 3D printed, high-performance rocket engine. Complex engine parts are being fired together with “cryogenic liquid hydrogen and oxygen to produce 20,000 pounds of thrust”. And according to David Eddleman, one Marshall’s propulsion designers, Additive Manufacturing has “really opened the design space and allowed for part geometries that would be impossible with traditional machining or casting methods.”

When these high-performance parts can withstand the stringent testing procedures of aerospace it will usher in a wave of new applications for more efficient airplanes and space shuttles.

Why Stop at Earth?

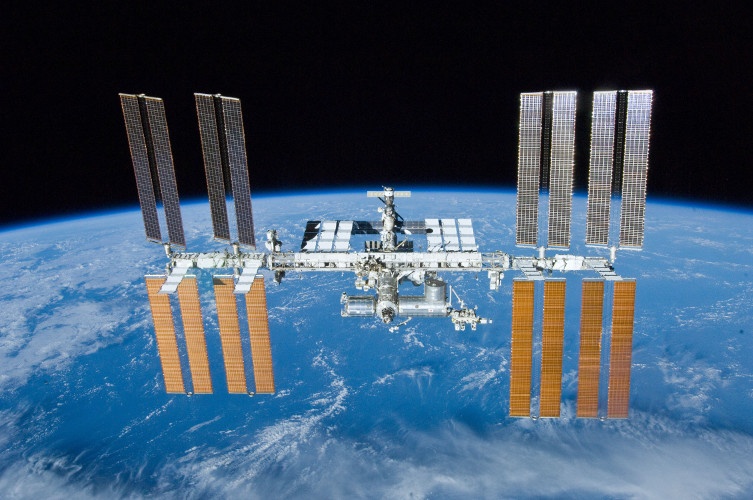

In 2014, NASA demonstrated the 3D printing of a tool on The International Space Station including the transfer of the design file of a ratchet wrench from the ground to the printer. As part of the printer's final test in that phase of operations, “NASA wanted to validate the process for printing on demand, which will be critical on longer journeys to Mars,’ explained Werkheiser.

Photo Source: Made In Space

Photo Source: Made In SpaceRemoving gravity from the production equation will again enable new forms to be created without using gravity. The effect will be similar to the forms that can be achieved with laser sintering. For space exploration, the potential to reuse raw materials in space by reducing and reprinting them into new forms would significantly remove the additional costs for sending raw material into space. We look forward to 3D printing as an enabler on the journey.