12 Pros and Cons of Digital Inventories

What's the big deal with digital inventories? In this article, explore 12 pros and cons of the growing shift to digital inventory management.

In the rapidly evolving landscape of modern manufacturing, digital inventories have emerged as a pivotal solution to address the challenges posed by legacy equipment.

Digital inventories encompass a comprehensive and organized repository of digital representations of physical parts, components, and equipment used in the manufacturing process. This strategic transition from physical to digital assets empowers manufacturing companies with the means to efficiently manage, access, and sustain their legacy equipment using additive manufacturing methods.

By embracing digital inventories, these companies can unlock the potential for streamlined operations, optimized maintenance, and cost-effective production, ensuring the continued relevance and productivity of their longstanding machinery and processes. But is it all it's cracked up to be?

6 Pros of Digital Inventories:

1. Efficiency and Accessibility:

Having a digital inventory allows for quick and easy access to part files, reducing the time spent searching for physical parts files. This can improve overall workflow efficiency and reduce production delays.

2. Reduced Physical Storage Needs:

Storing digital files requires significantly less physical space compared to storing physical parts. This can free up valuable space in your facility and reduce storage costs.

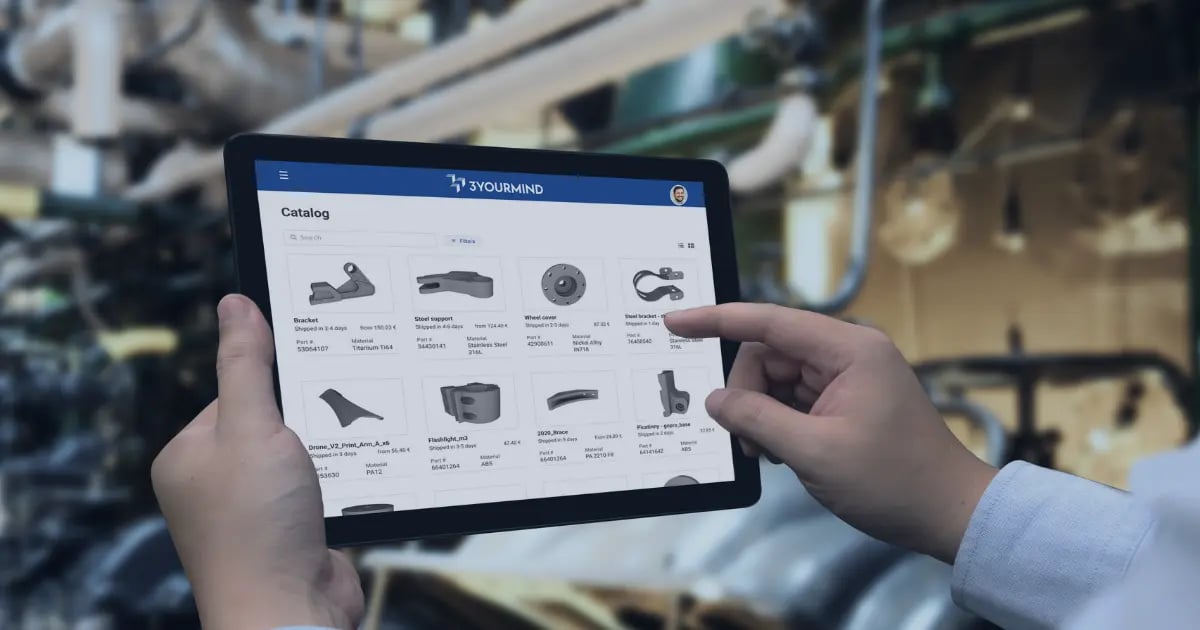

3YOURMIND's Digital Inventory software allows you to view and order parts securely from approved suppliers with accurate, automatic price quoting.

3. Version Control and Revisions:

Digital inventories can facilitate version control and tracking of revisions for each part. This ensures that the most up-to-date design is used, minimizing errors and improving consistency.

4. Collaboration and Sharing:

Digital inventories can be easily shared and accessed by various teams within your facility, as well as with external partners or suppliers. This promotes better collaboration and communication.

Read: See how 3YOURMIND makes collaboration between teams easier with new internal comments functionality.

5. Customization and Iteration:

Digital inventories enable easier customization and iteration of parts. Design changes can be made more quickly, and new prototypes can be produced without physically storing each iteration.

6. Reduced Lead Times:

With a well-organized digital inventory, you can reduce lead times for production since you can quickly identify and retrieve the necessary part files. Because parts files are already optimized and qualified for 3D printing, ordering parts is as simple as selecting from an approved supplier.

For example, the Easy3D platform, a collaboration between leading chemical manufacturer Arkema and 3YOURMIND, allows customers can order parts from suppliers based on material availability and suggestions.

6 Cons of Digital Inventories:

1. Initial Effort and Investment:

Building a digital inventory requires an upfront investment of time and resources to scan, categorize, and organize existing part files. This effort can be significant, especially if you have thousands of files.

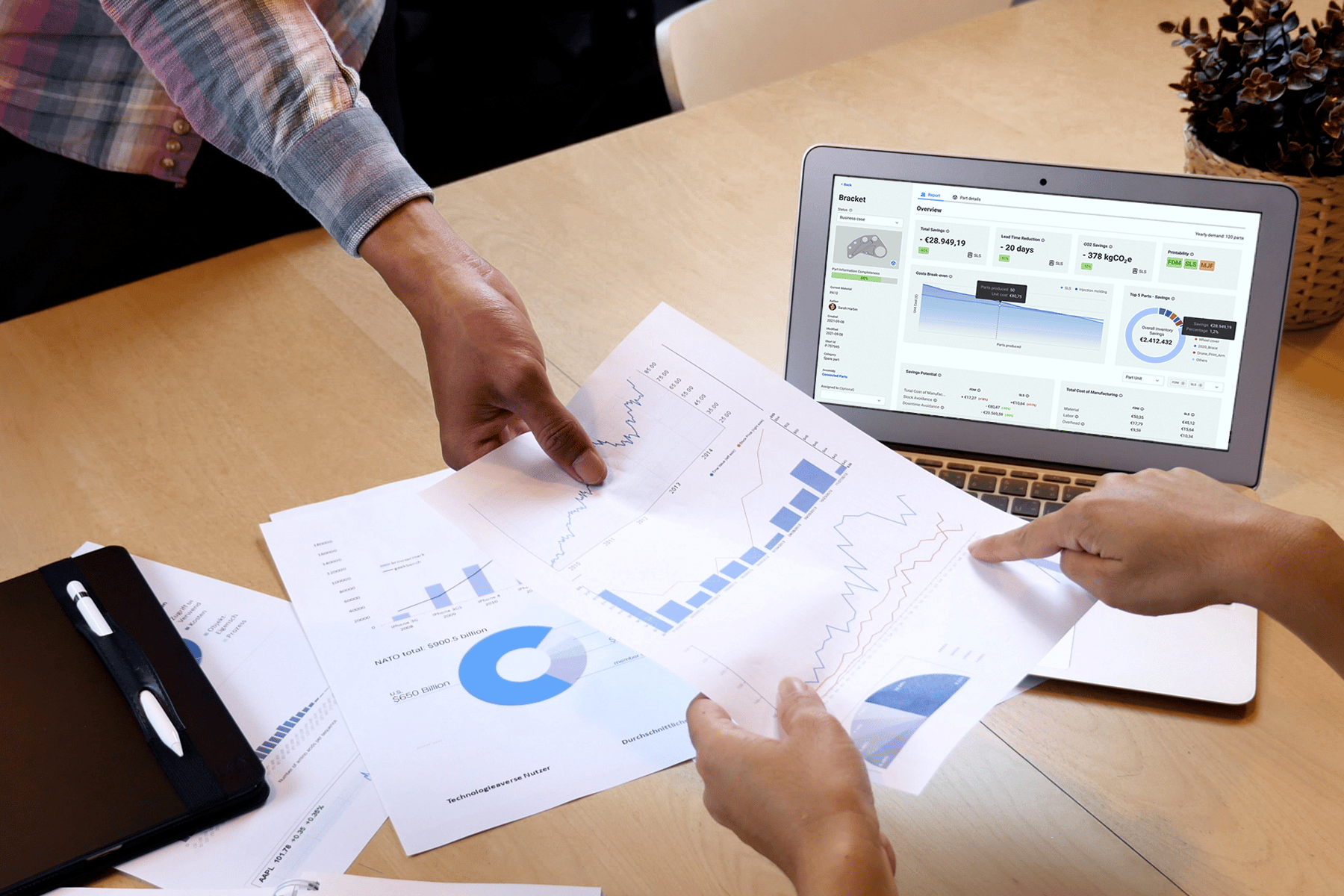

Fortunately, part identification solutions like 3YOURMIND's part screening and business cases streamline this process by up to 65% – helping companies focus their knowledge and resources only on the parts that matter.

2. Digital Security and Data Management:

Maintaining the security of digital files is crucial. Implementing proper data management practices and cybersecurity measures is essential to protect your intellectual property and sensitive information.

3YOURMIND sets itself apart with its industry-leading security protocol and on-premise installations, which is why we're a trusted partner of the U.S. Marine Corps. and U.S. Navy. Learn more about our approach to security here.

3. Learning Curve:

Transitioning to a digital inventory system might require training for your staff to ensure they are comfortable with the new tools and processes. Resistance to change could lead to initial productivity slowdowns.

4. Dependency on Technology:

Digital inventories rely on technology, which can be vulnerable to technical issues, data loss, or software compatibility problems. Contingency plans should be in place to address these issues.![]()

At 3YOURMIND, we understand that your operations require the use of multiple software tools. That's why we are an open API platform that is compatible with other software in your tech stack. Plus, we offer both cloud-based and on-premise software installations so that your tools are available wherever you are – with or without an internet connection.

5. Data Integrity and Quality Control:

Ensuring the accuracy and integrity of the digital part files is important. Mistakes or discrepancies in digital data can lead to errors in production.

6. Maintenance and Updates:

Digital inventories require ongoing maintenance to ensure that files are properly categorized, updated, and relevant. Without regular maintenance, the inventory may become disorganized and less useful over time.

However, compared to maintaining massive archives of two-dimensional drawings used for sustaining legacy equipment, maintaining digital inventories is a simplified investment in manufacturing's future – not it's past.

Digital Inventories: A Stepping Stone on the Path to Industry 4.0

Industry 4.0 is coming. Is your business prepared for it?

Digital inventories of 3D printable parts offer significant benefits in terms of efficiency, accessibility, collaboration, and reduced storage needs. However, there are challenges related to initial setup, data management, cybersecurity, and potential technical issues, which should be considered before committing to a major investment.

Before making a decision, it's important to weigh these pros and cons based on your specific manufacturing facility's needs, resources, and goals.

Want to talk to an expert to see if digital inventory is right for your business?

Let's set up a call to discuss whether 3YOURMIND can help!