What is a Digital Supply Chain and Why is it Important?

Tired of supply chain bottlenecks? Discover why the digital supply chain is the next big trend in manufacturing.

What is a Digital Supply Chain?

A digital supply chain refers to integrating digital technologies and processes to manage the entire supply chain. This includes using tools such as big data analytics, artificial intelligence, the Internet of Things (IoT), blockchain, and cloud computing.

What are the Benefits of a Digital Supply Chain?

The digital supply chain offers many benefits, including increased visibility and transparency, improved stakeholder collaboration, enhanced efficiency and productivity, better risk management, and reduced costs. With the help of advanced analytics, companies can gain deeper insights into customer behavior, demand patterns, and supply chain performance, enabling them to make more informed decisions and optimize their operations.

IoT devices like sensors and RFID tags allow companies to track and monitor their inventory and assets in real-time, enabling more accurate and timely forecasting and planning. Implementing blockchain technology helps create a tamper-proof and secure digital ledger of all transactions in the supply chain, ensuring transparency and reducing the risk of fraud and errors.

Additive Manufacturing and Digital Supply Chain

Additive manufacturing and digital supply chain are interconnected concepts that have revolutionized how goods are produced, distributed, and consumed.

Additive manufacturing, also known as 3D printing, creates three-dimensional objects by adding layer upon layer of material based on a digital design. Unlike traditional manufacturing methods that involve subtractive processes like cutting, drilling, and milling, additive manufacturing is an additive process that uses digital data to create a physical product.

Digital supply chain, on the other hand, refers to using digital technologies to optimize and streamline the entire supply chain process, from sourcing raw materials to delivering finished products to customers. This includes using digital platforms to manage inventory, track shipments, and monitor quality control.

The relationship between additive manufacturing and the digital supply chain is symbiotic. Additive manufacturing is a key component of the digital supply chain because it enables on-demand, decentralized production closer to the point of consumption. This reduces the need for extensive, centralized manufacturing facilities and long supply chains, which can result in cost savings, faster turnaround times, and reduced carbon footprint.

The digital supply chain enables additive manufacturing by providing the necessary infrastructure for sourcing raw materials, managing inventory, and delivering finished products. Digital platforms can be used to track the progress of a 3D printing job, manage the distribution of finished products, and even optimize the design of a product based on customer feedback.

3YOURMIND: Connecting Additive and Digital Supply Chain

3YOURMIND is a software company that provides solutions for optimizing and automating the additive manufacturing (AM) process. The company's platform enables a digital supply chain by connecting all the players involved in the AM value chain, from designers to manufacturers to end-users.

Parts uploaded to 3YOURMIND's digital inventory can be produced globally through distributed manufacturing facilities and approved suppliers.

Here are some of the ways in which 3YOURMIND enables a digital supply chain:

1. Digitizing the supply chain: 3YOURMIND's platform enables digital communication between all the players in the supply chain. This includes submitting digital files for 3D printing analysis, building digital inventories of 3D parts, and order management. Collaborators can submit comments, request changes, and order parts directly through the platform, eliminating the need for extraneous e-mails and phone calls to boost efficiency and transparency.2. Streamlining workflows: The platform also automates many of the processes involved in 3D printing, from file preparation to job scheduling and quality control. This reduces the need for manual intervention and streamlines the entire workflow.

3. Ensuring quality control: 3YOURMIND's platform includes quality management features that enable manufacturers to qualify parts for 3D printing 50% faster than manual qualification. As a result, companies can build qualified digital part inventories faster and start producing parts on demand.

4. Increasing transparency and traceability: The platform provides visibility into every stage of the supply chain, from file submission to delivery. This enables manufacturers to track the progress of each order and provide end-users with real-time updates on the status of their parts.

Overall, 3YOURMIND's platform enables a more efficient, transparent, and flexible digital supply chain for additive manufacturing. By automating many of the processes involved in 3D printing and connecting all the players in the supply chain, the platform enables faster turnaround times, reduced costs, and higher-quality parts.

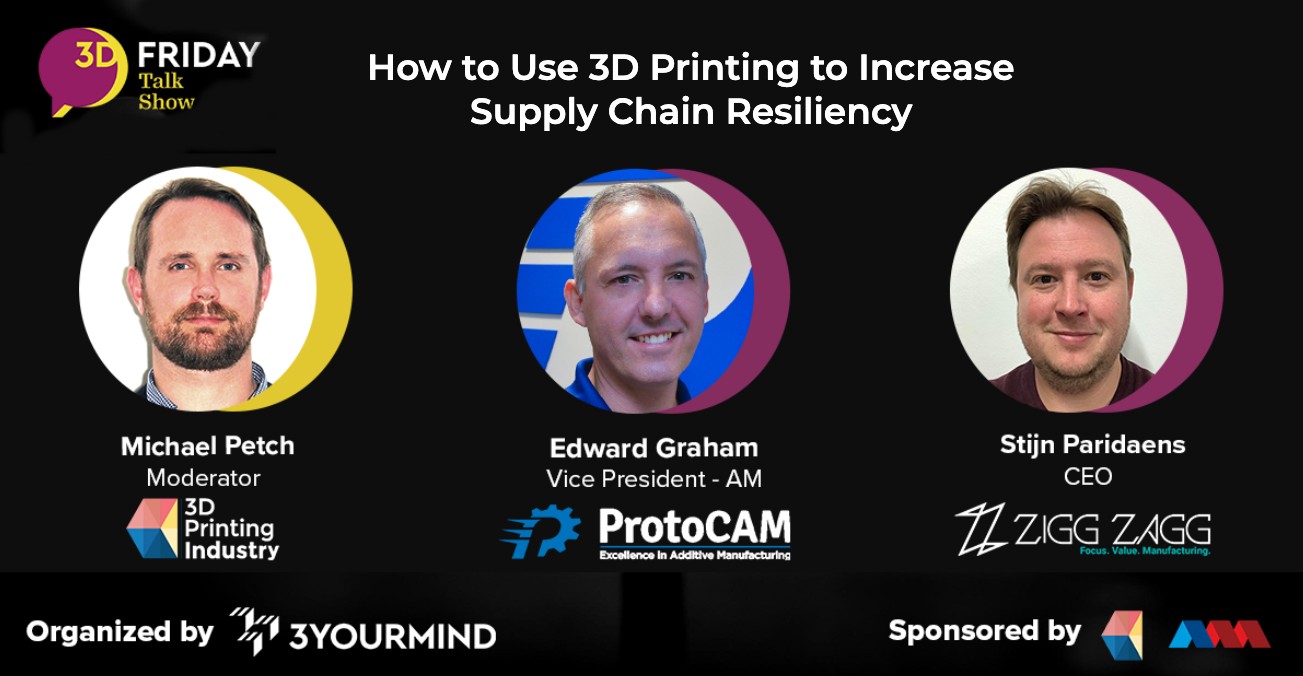

Watch Experts Discuss 3D Printing and Digital Supply Chain

Want to learn more ways 3YOURMIND supports digital supply chain? Connect with one of our experts!